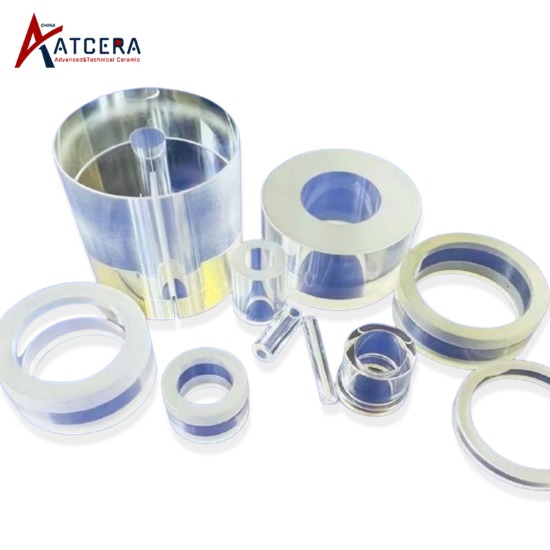

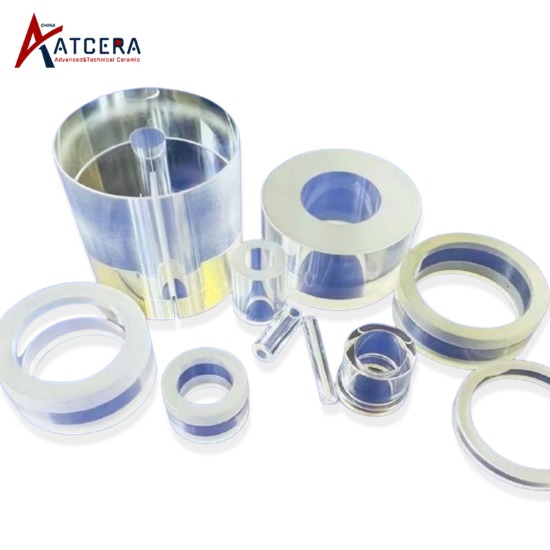

كنوع من المواد عالية الأداء، السيراميك الشفاف يظهر إمكانات تطبيق كبيرة في البصريات والإلكترونيات والفضاء وغيرها من المجالات بسبب انتقال الضوء الفريد والقوة العالية والاستقرار الحراري الجيد. ومع ذلك، فإن عملية تحضير السيراميك الشفاف معقدة، وخاصة عملية التلبيد، والتي ترتبط مباشرة بالخصائص النهائية للمادة. من بين العديد من طرق التلبيد، أصبح الضغط المتوازن على الساخن أحد التقنيات الرئيسية لتحضير السيراميك الشفاف عالي الجودة بمزاياه الفريدة. في هذه المقالة، سيتم مناقشة مبدأ وخصائص وتطبيق تقنية تلبيد الضغط المتوازن الساخن في تحضير السيراميك الشفاف بعمق، من أجل توفير مرجع للبحث والتطوير في المجالات ذات الصلة.

نظرة عامة على تقنية التلبيد بالضغط المتوازن الساخن

يجمع التلبيد متساوي الضغط الساخن بين مزايا الضغط متساوي الضغط في درجة الحرارة العادية والتلبيد في درجة حرارة عالية، ويحقق تلبيدًا موحدًا وفعالًا لقطع السيراميك من خلال تطبيق الضغط متساوي الضغط على الغاز الواقي في وعاء الضغط العالي.

مزايا انتظام الضغط المتوازن

بالمقارنة مع طريقة التلبيد التقليدية، فإن الضغط المتوازن على الساخن يطبق نفس الضغط في جميع الاتجاهات من خلال غاز الحماية من الضغط العالي، والذي يتجنب بشكل فعال العيوب الناجمة عن الضغط غير المتساوي داخل الجسم، مثل الشقوق والتشوه وما إلى ذلك، وبالتالي تحسين المحصول والخصائص البصرية للسيراميك الشفاف.

دور الغازات الواقية

إن اختيار الغازات الواقية المناسبة (مثل الأرجون والنيتروجين وما إلى ذلك) لا يمنع فقط أكسدة السيراميك أثناء عملية التلبيد ذات درجة الحرارة العالية، ولكن أيضًا يقلل من فقدان القالب، ويضمن النقاء والاستقرار بيئة التلبيد، وتوفير ضمانة قوية لتحضير السيراميك الشفاف عالي الجودة.

إمكانية تطبيق تلبيد الضغط المتوازن الساخن

هذه التكنولوجيا مناسبة للعديد من أنواع المواد الخزفية الشفافة، بما في ذلك على سبيل المثال لا الحصر الألومينا، ونيتريد الألومنيوم، وأكسيد الإيتريوم، وما إلى ذلك، مما يظهر نطاقًا واسعًا من قدرة المواد على التكيف ومرونة العملية.

باختصار، فتحت تقنية التلبيد بالضغط المتوازن على الساخن طريقًا جديدًا لتحضير السيراميك الشفاف من خلال طريقة تطبيق الضغط الفريدة والتحكم الجيد في بيئة التلبيد. فهو لا يحل المشاكل الشائعة المتمثلة في الضغط غير المتساوي والتلوث بالأكسدة في طرق التلبيد التقليدية فحسب، بل يعمل أيضًا على تحسين انتقال الضوء والخصائص الميكانيكية والاستقرار الحراري للسيراميك الشفاف بشكل كبير. مع التقدم المستمر لعلوم وتكنولوجيا المواد، من المتوقع أن تحقق تكنولوجيا التلبيد بالضغط المتوازن على الساخن توسعًا في التطبيق في المزيد من المجالات، وتعزيز تطوير المواد الخزفية الشفافة لأداء أعلى واتجاه تطبيق أوسع. في المستقبل، سيكون تحسين معلمات التلبيد واستكشاف أنظمة مواد السيراميك الجديدة بمثابة اتجاه مهم لأبحاث تكنولوجيا التلبيد بالضغط المتوازن الساخن، من أجل مواجهة التحديات الجديدة للتنمية العلمية والتكنولوجية وطلب السوق بشكل مستمر.